- Overview

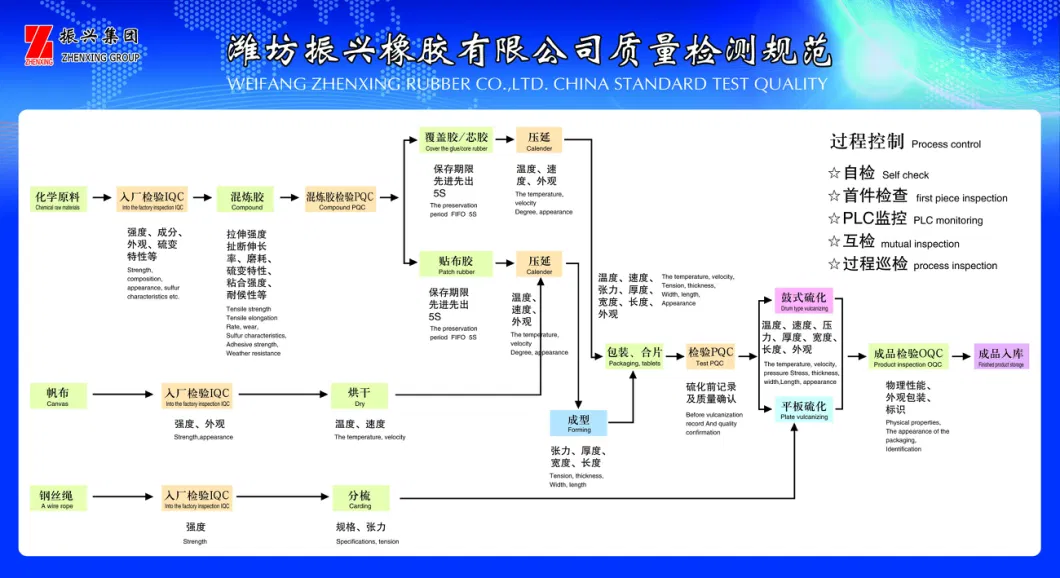

- Produce Rubber Conveyor Belt

- You may also Like

- Our Advantages

- Welcome Visit Us

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Wire Rope Core Conveyor Belt are suitable for medium and long distance, heavy load and high-speed transportation of materials, which is widely used in mines.

Comparison Table of EU EN14973 Underground Flame Retardant Steel Cord Conveyor Belt Safety Grade and CHINA MT668 Underground Flame Retardant Steel Cord Conveyor Belt Safety Grade Corresponding Parameters

| Grade | Application | Surface resistance EN ISO 284 | Drum friction EN1554:1998, B2a | Ignition EN ISO 340 | FIRE PROPAGATION METHOD See footnotes c-g for requirements | |||

| Flame | Glow | Maximum drum temperature /°C | Aggregate of each set of six test pieces/s | Maximum for any one test piece/s | ||||

| C1 | As Class Bl plus combustible dust or material conveyed. No secondary safety devices | ≤300 MΩ | No | No | 325 | ≤18 / 30b | 10/15b | EN 12881-1:2005, method Bd or Ce |

| a EN1554:1998, Due to the structure of the conveyor belt, Method B l may be used where Method B2 cannot be used due to belt construction, e.g. steel cord conveyor belts. b Values following tests with covers and without covers, respectively. | ||||||||

| Grade of covering Rubber: Tensile strength ≥ 17Mpa, Elongation at break ≥ 350%, Abrasion ≤ 175mm3 | ||||||||

| GB International Standard Underground Conveyor Belt Safety Level Outline | ||||||||

| Grade | Application | Surface resistance MT 450-1995 | Drum friction MT450-1995 | Ignition MT450-1995 | FIRE PROPAGATION METHOD See footnotes c-g for requirements | |||

| Flame | Glow | Maximum drum temperature /°C | Aggregate of each set of six test pieces/s | Maximum for any one test piece/s | MT914-2007 | |||

| MT668 -2019 | Flame retardant steel cord conveyor belt for coal mine | ≤300 MΩ | No | No | 325 | 3/10 (with rubber cover) | 5/15 (No rubber cover) | The sample length is 1500mm and width is 230mm. The ignition time is 50 minutes; The combustion performance of Roadway propane shall meet one of the following two requirements: |

| Grade of rubber cover: Tensile strength ≥ 15Mpa, Elongation at break ≥ 350%, Abrasion ≤ 200mm3 | ||||||||

a) The minimum undamaged length of the full width of each sample shall not be less than 600mm;

b) The minimum full width of the sample is the damaged length, which shall not be less than 50mm, and the maximum average temperature rise shall not be greater than 140 ºC

The damaged length shall not exceed 1250mm;

Note: EU C1 and MT668 alcohol burner burning test

The sample length is 2m , width is 1200mm if the bandwidth is ≥ 1200mm, and the sampling width is less than 1200mm according to the full width of the belt. It is required to leave the pattern on the bracket 10 minutes after ignition until all flames or sparks are extinguished;

The combustion performance of tunnel fire resistant shall meet the requirements that the unbroken full width belt length shall be ≥ 100mm.

If the sample length is 2500 mm, the bandwidth is 1200 mm or more, the sample width is 1200 mm, and if the bandwidth is less than 1200 mm, the pattern width is the bandwidth width; The ignition time is 20 minutes;

The tunnel fire resistant combustion performance meets the requirements: there is an undamaged belt.

The sample is 1500mm long and 230mm wide. The ignition time is 50 minutes; The combustion performance of tunnel fire resistant shall meet one of the following two requirements:

a) The minimum undamaged length of the full width of each sample shall not be less than 600mm;

b) The minimum undamaged length of the full width of the sample shall not be less than 50mm, the maximum average temperature rise shall not be greater than 140 ºC, and the damaged length of the sample in the form of mass shall not be greater than 1250mm;

(1)Q: Are you a factory or trading company?

A: We are a factory with an export license. We have the most convenient transportation conditions.

(2)Q: Do you offer samples?

A: We are glad to offer you free samples. New clients are expected to pay for the delivery cost, this charge will be deducted from the payment for the order.

(3)Q: How about the lead time?

A: Within10-20 days after getting the prepayment or L/C.

(4)Q: How can we pay?

A: For a small sample shipping costs, you can pay either by PayPal or by T/T. And by T/T or L/C at sight for a large amount of the order.

(5)Q: Can you do CO, Form E, Form F, Form A, etc?

A: Yes, we can do them for you.

(6)Q: What is your factory's main product?

| No. | Rubber Conveyor Belt |

| 1 | Conveyor Belt for General Purpose |

| 1.1 | EP(polyester) Conveyor Belt: EP100,EP125,EP150,EP200,EP250,EP300,EP400,EP500,EP630 |

| 1.2 | NN(Nylon) Conveyor Belt : NN100,NN125,NN150,NN200,NN250,NN300,NN400,NN500,NN630 |

| 1.3 | Cotton Conveyor Belt: CC-56 CC70 |

| 1.4 | Steel Cord Conveyor Belt: ST630,ST800,ST1000,ST1250,ST1600,ST2000,ST2500,ST3150,ST4000,ST4500,ST5000, ST5400 |

| 2 | Conveyor Belt for Special Purpose |

| 2.1 | Heat Resistant Conveyor Belt |

| 2.2 | High-Temperature Conveyor Belt |

| 2.3 | Fire Retardant Conveyor Belt |

| 2.4 | Cold Resistant Conveyor Belt |

| 2.5 | Oil Resistant Conveyor Belt |

| 2.6 | Chemical Resistant Conveyor Belt |

| 3 | Chevron (PaConveyor Belt |

| 4 | Bucket Elevator Conveyor Belt |

| 5 | Sidewall Conveyor Belt |

| 6 | Flat Transmission Belt |