Basic Info.

Model NO.

SYSE Spiral Conveyor

Condition

New

Roller Material

Stainless Steel/Plastic

Frame Material

Stainless Steel/Carbon Steel

Parameter

Customized

Usage

Vertical Conveying

Lifting Height

1-20m

Spiral Width

200mm/300mm/400mm/600mm

Handled Object

Boxes/Bags/Baskets/Bundles/Bottle/Rolls

Clarified by Transport Carrier

Chain Plate/Roller/Wire Mesh/Belt

Total Spiral Length

Carbon Steel Bottom Chain 60m/Stainless Steel Bott

Power

0.75kw-3.7kw

Linear&Nbsp;Speed

1m/S-30m/S

Speed Control Mode

Fixed Speed/Stepless Speed/Variable F

Screw Radius

650mm-1300mm

Guardrail

Aluminum Track,Wear Strip

Transport Package

No Packing

Specification

Stainless Steel/Carbon Steel

Trademark

No Brand

Origin

China

Production Capacity

500pieces/Year

Product Description

Spiral Transmission Conveyor Food Product Plant Oil Vertical Lifter

Spiral Conveyor Introduction

Spiral conveyor transports products up or down in a continuous flow, and has proven to be a very reliable concept in Vertical Conveying. Vertical conveying system does not only increase efficiency, it is also designed to conserve valuable floor space.

Spiral Conveyor Application

Spiral conveyor can convey bags, bundles, totes, trays, cans, bottles, containers, cartons and wrapped and unwrapped items. It is widely used in several industries, such as food industry, beverage industry, newspaper industry, pet food & personal care industry and many others.

Structure

The main components including: main frame, carrier chain, carrier chain guide, guardrail, power motor, frequency converter etc.; The materials and model are designed according to customer's need.

Spiral Conveyor Features

Spiral Conveyor Features

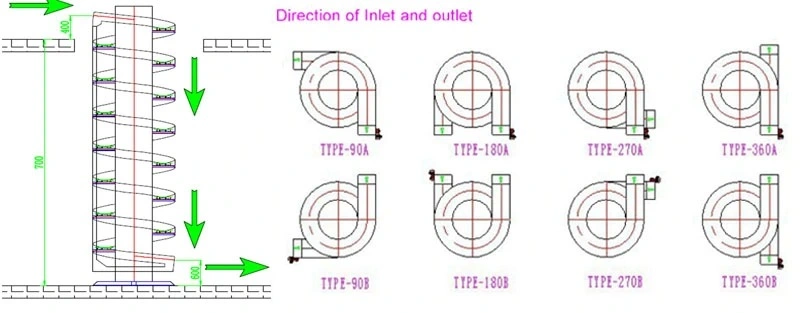

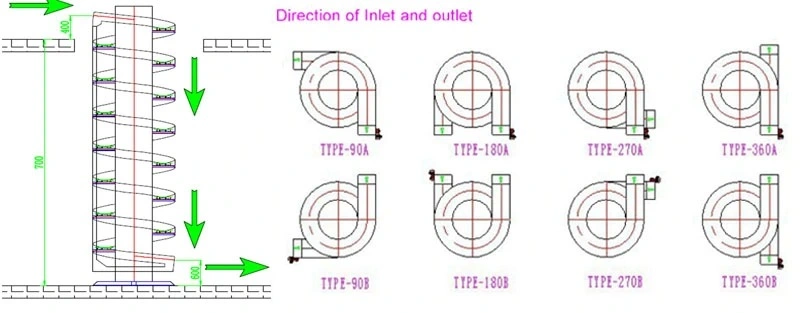

1. Reasonable and simple structure, easy maintenance, adjustable outlet.

2. Low power consumption, low noise.

3. Dust-proof, heat-proof, oil-proof and explosion-proof.

4. Two types available to choose: open type and sealed type.

5. Small space occupation, totally sealed structure can effectively avoid dust and harmful gas pollution.

6. Material can be cooled or dried during the lifting process according to customer's special request.

Spiral Conveyor Technical Parameters

Spiral Conveyor Pictures

Packaging & Shipping

Generally packed in 20ft or 40ft container;

Shipment within 10~20 working days after the advance/full payment

About Us

Zhengzhou Syoung Machinery Co., Ltd. is specialized in manufacturing and exporting transmission conveyors and equipment for decades.

All kinds of conveyors such as roller conveyor, belt conveyor, chain conveyor, wire mesh conveyor, screw conveyor, flexible conveyors are supplied to satisfy your different transmission demands.

We have professional technical engineer team, who have more than 20 years experience in transmission conveyor solutions for different fields.

Be your best and professional transmission solution partner is our pursue.

Our Service

1. Project Design

Offer best transmission conveyor solutions according to customers' demands.

2. Response within 24hour

Inquiries, questions and messages from customers will be responded within 24 hours.

3. Installation Training

Provide all-sided equipment installation guidance include but not limited to offer installation instructions, telephone guidance, help to train customers' workers through video session or site instruction.

4. After-sale service

24 hours online for technical consulting service, one year warranty, life-long maintenance; long-term technical support.

If you are interested in this product, please feel free to contact Ms. Sharon, Thanks.

Spiral Conveyor Introduction

Spiral conveyor transports products up or down in a continuous flow, and has proven to be a very reliable concept in Vertical Conveying. Vertical conveying system does not only increase efficiency, it is also designed to conserve valuable floor space.

Spiral Conveyor Application

Spiral conveyor can convey bags, bundles, totes, trays, cans, bottles, containers, cartons and wrapped and unwrapped items. It is widely used in several industries, such as food industry, beverage industry, newspaper industry, pet food & personal care industry and many others.

Structure

The main components including: main frame, carrier chain, carrier chain guide, guardrail, power motor, frequency converter etc.; The materials and model are designed according to customer's need.

Spiral Conveyor Features

Spiral Conveyor Features1. Reasonable and simple structure, easy maintenance, adjustable outlet.

2. Low power consumption, low noise.

3. Dust-proof, heat-proof, oil-proof and explosion-proof.

4. Two types available to choose: open type and sealed type.

5. Small space occupation, totally sealed structure can effectively avoid dust and harmful gas pollution.

6. Material can be cooled or dried during the lifting process according to customer's special request.

Spiral Conveyor Technical Parameters

| Clarified By Transport Carrier | chain plate, roller, plastic mesh, metal wire mesh |

| Spiral Conveying Width | 200mm, 300mm, 400mm, 600mm |

| Total Spiral Length | carbon steel bottom chain 60M, stainless steel bottom chain 48M |

| Main Frame Material | painting carbon steel and stainless steel |

| Lifting Height | 1.Highest 6M by single driven,but vary according to loading speed and load capacity match with the total spiral length. 2.Highest 20chain plate,roller,wire mesh,beltM by several units combination. |

| Max Load Capacity(one driven) | carbon steel bottom chain<750kg,stainless steel bottom chain<600kg |

Spiral Conveyor Pictures

Packaging & Shipping

Generally packed in 20ft or 40ft container;

Shipment within 10~20 working days after the advance/full payment

About Us

Zhengzhou Syoung Machinery Co., Ltd. is specialized in manufacturing and exporting transmission conveyors and equipment for decades.

All kinds of conveyors such as roller conveyor, belt conveyor, chain conveyor, wire mesh conveyor, screw conveyor, flexible conveyors are supplied to satisfy your different transmission demands.

We have professional technical engineer team, who have more than 20 years experience in transmission conveyor solutions for different fields.

Be your best and professional transmission solution partner is our pursue.

Our Service

1. Project Design

Offer best transmission conveyor solutions according to customers' demands.

2. Response within 24hour

Inquiries, questions and messages from customers will be responded within 24 hours.

3. Installation Training

Provide all-sided equipment installation guidance include but not limited to offer installation instructions, telephone guidance, help to train customers' workers through video session or site instruction.

4. After-sale service

24 hours online for technical consulting service, one year warranty, life-long maintenance; long-term technical support.

If you are interested in this product, please feel free to contact Ms. Sharon, Thanks.